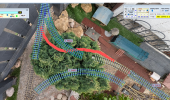

your curves under the fence dont line up properly.

I would take a longer turnout with a bigger radius for under the fence so your transaction curve wil have more tolerance.

For the piece "dead end line" i would place the turnout a bit futher down to the red stuff, even maybe the frog 4 inch/10cm after the red stuf, also here i would take a bigger radi turnout.

Then you would get away with tighter curves/transaction line between the two turnouts.

Two other ideas that require a bit more pain:

Place two new fence posts each 50cm/1.5feet away from the original fencepost and cut that one....

Or dig deep in your wallet and buy or make a crossover.

With the tight transaction curve s shape between your two new turnouts you can have clearance enough, but i am in doubt.

it can be done

View attachment 342574

start with cutting up the curve as you wish and put some flexitrack in the middle to connect them as a transaction curve.

i used a r0 turnout in this one but a r1 or r2 would be better.

Hope this was of any help

Ps for illustration i left the curves longer then they are ssuppost to be, i think 15cm/6inch would be more than adequte to start the transaction.

But it is tight....

Judging by the size of your cars, the clearance you have with the fence post would be enough.

best Igor