tac foley

Registered

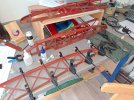

I've had my 'Earless' since a week after they appeared in the stores. Mine is still manual in GWR green and much-loved as a reliable performer, especially after a £300 rebuild by old pal Dave Mees a couple of years ago. SLR make the most exquisite and correct GWR red and white side-lamps - they work, too!A new locomotive has arrived at the railway. This lovely Accucraft countess, the second steam engine at the railway after the Edrig. Not had it in steam but possibly one for the weekend if time allows

View attachment 344234

View attachment 344235

Last edited: