A while back there was a Regner "Else" thread started by Jake in Oz:

Regner Else

which had 2 extra pages of discussion about distilled/deionized water. (If you fancy discussing water, please do it on that other thread.)

Some weeks towards the end of that thread, "ol hogger" posted a few pics of his loco, and Jake said his was for sale. In a moment of weakness, I bought the "Else" from Jake and it arrived yesterday from Australia.

I put it on rollers today and did all the usual stuff to get some steam pressure. I finally figured out the smokebox door opens, which helped. When I got 2 bar, I opened the throttle and nothing happened. After a few moments I realized I hadn't put it in forward (or reverse) gear - so where was the reversing lever? Hmmm . .

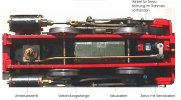

I turned off the gas and gently laid it on a towel on its side. Aha - a rotary valve for reversing. But nothing to make it do something.

That's my new engine from Jake above - as you can see, it had almost no wear. Below is the pic 'ol hogger' posted of his loco:

Mine seems a bit newer, but neither have anything attached to the rotary reverser. So the great mystery - how is the valve supposed to be operated, rotated, or whatever? I can't see sticking my finger underneath when it is hot.

P.S. I discovered (in the 2009 Regner Catalog) that Else, Emma and Frieda all share the same chassis, so anyone with one of them can possibly explain this little conundrum.

Regner Else

which had 2 extra pages of discussion about distilled/deionized water. (If you fancy discussing water, please do it on that other thread.)

Some weeks towards the end of that thread, "ol hogger" posted a few pics of his loco, and Jake said his was for sale. In a moment of weakness, I bought the "Else" from Jake and it arrived yesterday from Australia.

I put it on rollers today and did all the usual stuff to get some steam pressure. I finally figured out the smokebox door opens, which helped. When I got 2 bar, I opened the throttle and nothing happened. After a few moments I realized I hadn't put it in forward (or reverse) gear - so where was the reversing lever? Hmmm . .

I turned off the gas and gently laid it on a towel on its side. Aha - a rotary valve for reversing. But nothing to make it do something.

That's my new engine from Jake above - as you can see, it had almost no wear. Below is the pic 'ol hogger' posted of his loco:

Mine seems a bit newer, but neither have anything attached to the rotary reverser. So the great mystery - how is the valve supposed to be operated, rotated, or whatever? I can't see sticking my finger underneath when it is hot.

P.S. I discovered (in the 2009 Regner Catalog) that Else, Emma and Frieda all share the same chassis, so anyone with one of them can possibly explain this little conundrum.

Last edited: