Condensation and rain.

I asked this of the Google bot (dive into AI Deeper) "I have some solenoid point motors that I want to use out in a garden railway setting. How would I protect them from the weather and keep moisture out of the coils and the actuating bar"

and this was the answer

To protect solenoid point motors in an outdoor garden railway setting, you need a multi-faceted approach focusing on sealing the unit and ensuring proper drainage and physical protection

Key Strategies for Weatherproofing

- Use a Weatherproof Enclosure: The most effective way is to house each point motor inside a standard, commercially available weatherproof electrical junction box. Look for an IP65 rating or higher, which guarantees the enclosure is dust-tight and protected against water jets (heavy rain).

- Seal All Entry Points:

- Wiring Entries: Use appropriate cable glands to seal where the wires enter the enclosure, ensuring a tight, waterproof seal around the cable sheaths.

- Actuating Bar Opening: This is the most challenging part. A small opening is needed for the actuating bar to connect to the point tie-bar. Pack this area generously with a heavy, compatible grease such as silicone grease or even petroleum jelly (Vaseline) to repel water and prevent rust on the metal parts. This grease needs regular checking and re-application as it may attract dirt over time.

- Enclosure Seals: Ensure the lid of your junction box has an intact gasket and is screwed down properly to maintain its IP rating.

- Manage Water Flow: Position the enclosure and/or add a "rain hood" or drip shield above it to prevent water from pouring directly onto the unit or the actuating bar opening.

- Lubricate Metal Parts: The internal metal components of standard point motors (like the steel return spring and the core) are prone to rusting outdoors. Lubricate them with silicone grease or petroleum jelly to prevent corrosion, but avoid general purpose oils like WD40 which can dry into a gummy residue.

- Ensure Access for Maintenance: Do not permanently seal the enclosure or glue down any covers (such as a scenic building placed over a surface-mounted motor). You will need regular access for inspection, lubrication, and troubleshooting.

- Consider Alternative Motors (If possible): For a new garden railway, you might consider motors specifically designed for outdoor G scale use (like some LGB models) which are built to be more resilient, although even these can benefit from protection and maintenance.

By taking these precautions, you can significantly extend the life and reliability of standard solenoid point motors in an outdoor environment.

From this start point I would follow most of the instructions.

For the actuating rod I would look at using a rod in tube to isolate the motor actuating pin something a clevis on the pin and

A big consideration will be how to get the point motor to stay in its activated position once it has thrown it should be OK if the points have over centre springs like HO ones but is there is not any you now have to figure out how to copy that.

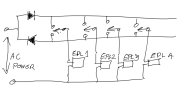

You cannot leave the solenoid coil powered continuously unless you plan to use it as a toaster as well. So now a Capacitive Discharge Unit(CDU) is required.

Again AI has suggestions to this question "How do I get the solenoid to stay in the same place once activated"

Standard model railway solenoid point motors are designed for

momentary power pulses and rely on either an internal or the point's built-in spring to hold the points in one position. Applying continuous power to a standard solenoid will cause it to rapidly overheat and burn out.

To make a solenoid "stay" in the same place without continuous power, you have a few options:

1. The Standard Model Railway Method: Rely on the Point's Spring

The intended way to use most model railway solenoids (like Peco or Hornby) is to let the points themselves provide the "latching" or holding mechanism.

- How it works: The points' tie-bar has a built-in over-centre spring. When the solenoid gets a brief power pulse, it throws the points, and the spring holds them firmly against the stock rail in that new position. When you pulse the other coil, the process reverses.

- Action: Ensure your point motors are connected to a momentary switch (one that springs back to the off position when released) or a passing-contact lever switch. Use a Capacitor Discharge Unit (CDU) to provide a strong, safe pulse of power and prevent burnout.

2. The Latching Solenoid Method (Different Hardware)

If you require the motor mechanism itself to hold the position without power, you would need to use a different type of solenoid altogether: a

latching solenoid.

- How it works: These solenoids use a permanent magnet or residual magnetism to hold their position after a power pulse is applied. A pulse of opposite polarity is then required to release and move it to the other position.

- Action: Purchase a latching solenoid and use an H-bridge circuit or specific latching relay control system to send the necessary polarity-reversed pulses. These are less common in traditional model railroading but are used in industrial and irrigation systems.

3. The Latching Relay Method (External Circuitry)

You can use a standard solenoid but manage its state with an external electronic circuit that "remembers" the last command.

- How it works: You install a separate latching relay or a simple memory circuit (like a flip-flop or an Arduino-based controller). The relay toggles its internal state with each momentary input, and its contacts provide continuous power to the point motor only at the moment of switching, or rather, switch the frog polarity and rely on the point spring to hold the position.

- Action: Wire a latching relay into your control panel. The momentary activation of the point motor also toggles the state of the relay, which controls the frog polarity and route indication lights.

In summary, for standard model railway solenoids, the key is using

momentary power and relying on the points' own mechanism to hold position.

Final question "Is there any way I can use them with points with no springs"

It is strongly recommended that you

do not use standard solenoid motors with points that have no springs

, as the motors are non-latching and require the point spring to hold the point blades firmly against the stock rail. Without a spring or a locking mechanism, the points may not make good electrical contact and can vibrate or move freely, causing derailments.

Here are the ways you can address this:

Recommended Solutions

- Reinstate the Point Spring: The simplest and most reliable solution is to refit the over-centre springs to your pointwork if you intend to use standard solenoid motors. The spring provides the crucial holding force once the momentary power pulse from the solenoid is removed.

- Add a Separate Mechanical Latching Mechanism:

- External Spring System: You can devise an external spring system that attaches to your push rod setup (from the previous suggestion) to provide the necessary over-centre force, effectively adding a spring back into the system externally.

- Friction Devices: Some modelers have used an extra electrical connector block with its screws adjusted to provide the right degree of friction to hold the point blades in place. This is a more DIY approach but has been reported to work.

- Use the Right Type of Motor: If you are committed to using springless points, standard solenoids are the wrong tool for the job. You should use stall motors (like the Tortoise or Cobalt models) or servo motors.

- These motors are designed to operate without the point spring. They use continuous power (stall motors) or a high-friction gear mechanism (servos) to provide a constant holding force and keep the points in position.

- These alternatives offer the added benefit of slow, realistic point blade movement, which is often preferred over the snap action of a solenoid

Standard solenoids are designed for quick, powerful bursts of current (best supplied via a Capacitor Discharge Unit (CDU)) and cannot handle continuous power. Do not attempt to hold them in place by

- leaving the power on, as this will burn out the coils. Hate to be a Debby Downer but personally I would look at an alternative method.

www.gaugemasterretail.com

www.gaugemasterretail.com