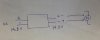

There must be a way to reduce the DC voltage to a small motor. The scenario I have is pictured below. Basically, it uses one of those R/C motor reversers to operate two functions on a crane i am working on. For clarity, I have shown only one of the exiting circuits, the one that powers and reverses the hook motor.

Power goes into the R/C motor reverser and exits +/- or -/+ depending on which button is pressed on the transmitter. 14.8 volts in and 14.8 volts out. I would like to reduce the power going out. I experimented with one of those tiny voltage reducers, wired into the exiting wiring. The problem with those is that they are polarity sensitive, so no matter command the motor reverser is given, the polarity does not change to the motor after exiting the voyage reducer. A resistor didn't prove successful either.

Power goes into the R/C motor reverser and exits +/- or -/+ depending on which button is pressed on the transmitter. 14.8 volts in and 14.8 volts out. I would like to reduce the power going out. I experimented with one of those tiny voltage reducers, wired into the exiting wiring. The problem with those is that they are polarity sensitive, so no matter command the motor reverser is given, the polarity does not change to the motor after exiting the voyage reducer. A resistor didn't prove successful either.