Polarblair

Registered

Hi All,

My parents gave my wee lad his first RC Playmobil set for his 4th birthday a few weeks ago. I still have my brass rail set stored away for when he is a bit older and had been collecting all sorts like the old train stations to flesh out the play experience for him.

Since the set arrived thing have gotten a little out of hand and now two bays of my workshop have been dedicated to the railway

I remember using Duplo to build bridges but had some scrap wood lying around so knocked that and a basic harbour together for him.

Choo Choo! This is definitely just for the boy - not me. Not at all.

Back to the turntable.

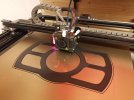

I set up a turnaround loop for him but this takes up a lot of track and space so started looking for a turntable assuming that surely Playmobil made one - no dice. The price of the ones I found ruled them out. Having successfully 3D printed a few straight tracks I set to work designing my own.

It's not modelled on anything specific and was initially very basic but I couldn't help myself. It's far from perfect and I've had to design my way out of a few problems as I started printing while still designing

I pulled a lazy susan bearing out of the carvan meant to swivel a CRT TV as a starting point and modelled around that.

I don't have a layout in mind so went for maximum flexibility with 12 tracks.

Plan is to use at least 3 for a train shed - still to be designed.

I don't know if my printer will manage fine detail like rivets so I've given myself the option of adding them later in copper filament. The red thing in the background is just a handle my son can use to turn the turntable.

So far so good. The pieces all snap together with connectors but I'll glue for final assembly.

The side rails look skinny as they're printed in two halves so I can have details on both inside and out without the need for supports.

I ended up thinking about adding detail like push handles or a hand crank and while looking online came across the above picture. Couldn't believe how close it was but given how many flavours turntables come in it shouldn't be too surprising. I did take one thing from this though. I like the angled support flanges/struts on the inside face of the bridges so I added them to the model.

I've ordered this walnut PLA made by AMOLEN for the planks and the timber support beams. Never had a good reason to fiddle with wood PLA but I like the idea of being able to lightly sand it for a nice Matt texture. At 30% wood content (apparently) it's undoubtedly going to be quite abrasive but nozzles are cheap!

I'll update once it arrives.

My parents gave my wee lad his first RC Playmobil set for his 4th birthday a few weeks ago. I still have my brass rail set stored away for when he is a bit older and had been collecting all sorts like the old train stations to flesh out the play experience for him.

Since the set arrived thing have gotten a little out of hand and now two bays of my workshop have been dedicated to the railway

I remember using Duplo to build bridges but had some scrap wood lying around so knocked that and a basic harbour together for him.

Choo Choo! This is definitely just for the boy - not me. Not at all.

Back to the turntable.

I set up a turnaround loop for him but this takes up a lot of track and space so started looking for a turntable assuming that surely Playmobil made one - no dice. The price of the ones I found ruled them out. Having successfully 3D printed a few straight tracks I set to work designing my own.

It's not modelled on anything specific and was initially very basic but I couldn't help myself. It's far from perfect and I've had to design my way out of a few problems as I started printing while still designing

I pulled a lazy susan bearing out of the carvan meant to swivel a CRT TV as a starting point and modelled around that.

I don't have a layout in mind so went for maximum flexibility with 12 tracks.

Plan is to use at least 3 for a train shed - still to be designed.

I don't know if my printer will manage fine detail like rivets so I've given myself the option of adding them later in copper filament. The red thing in the background is just a handle my son can use to turn the turntable.

So far so good. The pieces all snap together with connectors but I'll glue for final assembly.

The side rails look skinny as they're printed in two halves so I can have details on both inside and out without the need for supports.

I ended up thinking about adding detail like push handles or a hand crank and while looking online came across the above picture. Couldn't believe how close it was but given how many flavours turntables come in it shouldn't be too surprising. I did take one thing from this though. I like the angled support flanges/struts on the inside face of the bridges so I added them to the model.

I've ordered this walnut PLA made by AMOLEN for the planks and the timber support beams. Never had a good reason to fiddle with wood PLA but I like the idea of being able to lightly sand it for a nice Matt texture. At 30% wood content (apparently) it's undoubtedly going to be quite abrasive but nozzles are cheap!

I'll update once it arrives.