P A D

Registered

Hello everyone,

My name is Peter and I'm a new member and convert to G Scale. I've been an O gauge kit builder for over 30 years building loco kits mainly for my brother, but in recent years more for myself. Here are some examples of my work.

BR Standatd 4MT built from the Modern Outline Kit.

LMS 4P built from the David Andrew's kit.

BR 8P Duke of Gloucester built and painted by me from the Seven Models kit.

LMS Princess Coronation - Dutchess of Sutherland, built by md and professionally painted by Warren Hayward .

During the lockdown period and until recently, I've been building a plastic display model of the German Baureihe 86 from the Trumpeter Models kit. This was something completely new to me in terms of prototype, railway and the medium.

Building this latter kit has sparked my interest in German locomotives and prompted an internet search of what was available in terms of kits and RTR in the larger scales. In terms of kits there is zilch, but lots of RTR in gauge 0 and gauge 1, albeit at very high cost. During my searching, I discovered the Piko G gauge BR64, which I took a fancy to. Searches for reviews led me to G Scale Central where although I didn't find a review, I did find one for sale at a good price! That's the context of how I got here so on with the review.

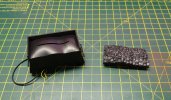

The model as purchased is in mint condition and came in the original box, with the additional detail parts still in the bag. Here's what it looks like out of the box.

And the other side. One of the first things that struck me was the colour of the wheels and the bare metal rims, so I quickly primed and repainted one of the front ponywheels to see how it would look. A big improvement to my eye.

I'm going to end it here for now and continue later, as I inadvertently opened the preview and can't close it and it's driving me mad having the post duplicated on the screen. I don't see the need for a preview when you can type and add images as you go and can see everything.

Cheers,

Peter

My name is Peter and I'm a new member and convert to G Scale. I've been an O gauge kit builder for over 30 years building loco kits mainly for my brother, but in recent years more for myself. Here are some examples of my work.

BR Standatd 4MT built from the Modern Outline Kit.

LMS 4P built from the David Andrew's kit.

BR 8P Duke of Gloucester built and painted by me from the Seven Models kit.

LMS Princess Coronation - Dutchess of Sutherland, built by md and professionally painted by Warren Hayward .

During the lockdown period and until recently, I've been building a plastic display model of the German Baureihe 86 from the Trumpeter Models kit. This was something completely new to me in terms of prototype, railway and the medium.

Building this latter kit has sparked my interest in German locomotives and prompted an internet search of what was available in terms of kits and RTR in the larger scales. In terms of kits there is zilch, but lots of RTR in gauge 0 and gauge 1, albeit at very high cost. During my searching, I discovered the Piko G gauge BR64, which I took a fancy to. Searches for reviews led me to G Scale Central where although I didn't find a review, I did find one for sale at a good price! That's the context of how I got here so on with the review.

The model as purchased is in mint condition and came in the original box, with the additional detail parts still in the bag. Here's what it looks like out of the box.

And the other side. One of the first things that struck me was the colour of the wheels and the bare metal rims, so I quickly primed and repainted one of the front ponywheels to see how it would look. A big improvement to my eye.

I'm going to end it here for now and continue later, as I inadvertently opened the preview and can't close it and it's driving me mad having the post duplicated on the screen. I don't see the need for a preview when you can type and add images as you go and can see everything.

Cheers,

Peter

Last edited: