Are you over thinking this?

If you are using set-track R3 curves, then you have the radius to track centre, and the angle of degree for each piece of curve.

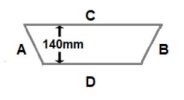

You probably want the joins between each piece of track in the middle of each of your boards. Measure the length (centre to centre) of an R3. This gives you the centre-length of one of your boards. Cut first angle. Measure length along centre, then cut the other end.

Once you have one correct, you can set up a stop, to get them all in the same.

However, if you want to use set-track for both inner and outer tracks, then one (or both) will have to be fudged, as the set geometry will not be correct.

If you are going to use flex-track, then you can set your own radii, and form the curves to fit.

Just a matter of deciding how close to the edge of each segment, you want the track to get.

Work to a constant angle of curve, for each segment of board (say 15 degrees?).

Otherwise, on curves, arrange supports, and use the boards across the supports.

Problem may be the boards are too wide, so gaps between each piece may be a little unsightly? - you would need to arrange to cover these, if you wish to ballast the track.

PhilP