Well, Time flies. I have progressed my little loco on a bit. I have asked around, and IP tin shunter bits seem to be like the proverbial rocking horse poo. I will therefore, have to put a body of my design on it. (Possible disaster alert.) I am now trying not to let it cost me anything but I will probably have to buy some Plastikard, MekPac and (definitely) screws.

So far, I have removed the gearbox as it was not up to the job. The wormwheel is fitted with a 12BA x 1/8” slotted head grubscrew, tightening this with any force at all results in the screw slot splitting and it still not being tight enough to attach the wormwheel to the axle to drive six wheels. I did consider Loctite (the blue stuff), but you risk gluing the lot solid as the wormwheel is captured by the 3D printed gearbox. What I mean to say is that the assembly would have to be glued in situ, therefore there is a (high for me) risk of getting glue on the bearings in the gearbox. I will find a railbus or some light duty vehicle to use it in. I managed to get one of those Indiana Jones Lorries (you know, the German thing with the “canvas” (plastic) cover on the back) before the prices on EBay went potty. It might be a fit in there for its use on rails.

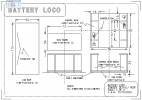

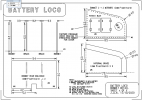

Instead of the proposed gearbox, I have used my usual method of a Slater’s wormwheel assembly, 4mm/2mm coupling and a MFA 15:1 Motor gearbox. (Yes, these were in my bits box, for a long abandoned idea.) I thought I had a sheet of Aluminium to make the footplate, but I couldn’t find it, so I have used some 3mm Plywood, braced with 10mm x 10mm x 1mm Aluminium angle iron (the (6BA) screws are in temporarily until I can get hold of some shorter ones). The angle iron is predrilled to accept the, yet to be made, body on top.

The back story for this loco, it is the result of a local Electrical Engineering firms attempt to build a viable, battery powered (neat uh?) shunting/trip locomotive. They built some 3 foot gauge locos as a test bed for the usual reasons railways built narrow gauge lines. The particular loco in my possession will have been used to demonstrate its usefulness in the military; therefore it will have a camouflaged livery. (Quite how I am going to paint that I don’t know, but YouTube will be my instructor. Every day is a school day with this hobby.)

If I can get a Pantograph for less than an arm and a leg, I would like to stick one of these on the cab roof. Then, of course I can say it is a “Bimode” locomotive. So on trend! (Anyone have a pan they want rid of?) I suppose I could make some sort of “tram-esque” collector hoop...

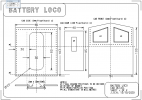

Body wise, I did give some thought to “steampunk”, post apocalyptic gibberish, but decided against it. I can’t see the point of sticking gearwheels on the side for no apparent reason. So I looked then at those NER Electrics. A sort of cut down and bodged version of these would suffice, I think. The rounded nose might be a step too far for my dubious plastic bending skills though. Or possibly a double ended loco with Hunslet shaped bonnets. These would be nice and simple to make but the bonnets will have to be full width due to the Aluminium plywood braces. Hey ho, I shall see what happens.

Whatever, there will be rivets to count. Last year, for my Birthday, my partner, (gawd bless ‘er) treated me to a Pdf Models Baldwin loco tractor and a very nice model it is too. However, I chickened out of applying the tiny, tiny rivets supplied with it to decorate the bonnet and cabs as I did not want to ruin it. This cobbled together loco will be a test bed for my riveting skills that I will then apply to the tractor...hopefully. I do have a bag of 1/32” rivets and I am flip flopping between these and the stick on ones. Like I said, every day is a school day with this hobby.

View attachment 274517

View attachment 274518