napalmdrinker

Registered

G'day, first time poster, so apologies if this is posted in the wrong place.

This'll also be a pretty loaded post, but I want to try to get all the information I've researched in one go. So apologies for how much there'll be.

I will also say, I have zero experience with wiring and soldering, so will be learning how it all works as I go along.

My goal is to convert my LGB LCE 70600 from the original track power, to remote control and battery power with a sound card as well, so I can just unpack it on whatever layout, and just turn it on and control it wirelessly with a controller.

And if possible, make it interchangable between track/battery power, track power not needing to be wirelessly controlled.

The whole train consists of 8 cars, a powered car at each end, with 6 intermediate between.

So far the only thing I know for certain I'd have to get would be an ESU LokSound 5 XL sound card, as they have a sound file that I like.

My problems start with that I'm not sure what else I need to get, or how any of it works.

Transmitter/Receiver:

--I've been looking into Deltang/RCT for a transmitter/receiver, with the Tx20 transmitter looking to be better suited for my needs, but then not knowing which receiver of the 2 they offer to go with. I'd only be needing a small amount of extra sounds, such as horn, station announcements etc, so the

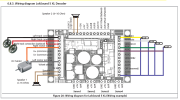

--The Rx102 (The RCT-Rx102 receiver) seems the more basic, and the wiring diagram they show on their page looks like what I think I;m going for. And the Rx65c (The RCT-Rx65b receiver) looks like it has more options for connecting to a sound card, and has a built-in esc, which sounds like a good thing?

--I'd also seen ESU has their own controller, the Mobile Control II, but they are horribly expensive, and I've got no clue what kind of receiver they work with.

Wiring:

--Given I've not done anything of the sort before, I've got no clue as to what wires go where, or how things work electrically.

--To go the cheaper route, I'll most likely go with the main workings at one end, i.e. battery, receiver, sound card, speakers, and have wires go through the train to the other end to power the other motor/speakers/directional light.

--I'd seen on another post on here that someone had used mini DIN plugs/sockets at each carriage connection to get them through and still be able to take the train apart for storage. Though I'd heard somewhere that having a long cable between power and motor has some kind of effect with resistance/power loss? Again, I have zero clue with electrics.

--With that, do different coloured wires do different things, or are they just to differentiate between uses? And if so, are there common colours for certain uses to stick to, or just go with whatever and remember what does what yourself?

Sound Card:

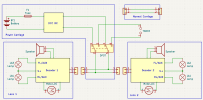

--The ESU LokSound 5 XL, from what I can tell, would best suit how I want it to sound. Apart from that, and from what little I've found, I wouldn't know as to how to it works. Such as what wires would go where? A diagram of what the terminals all do I found just ends up confusing me. Do wires for directional lights need to go straight from the receiver to the lights, or do they go through the decoder first? Do wires go to the from the receiver to the decoder and then to the motor?

--I'd be getting the ESU LokProgrammer to go with it so I could put on my own sound file from their site.

--From what I've seen, it looks like you just set certain terminals to a sound, and the receiver triggers it if a wire connects to it and is powered? I have yet to learn how increasing the speed of the train changes how the sound of the engine builds up, but I assume it detects power increase for the motor wires? Or axle rotation?

Battery:

--I've already got a good LiPo battery that I use for my R/C rock crawler car, so I'd hope to use that for this as well preferably.

--It's a 7.4V 5Amp LiPo battery, and have a fancy charger for it already. Would this be a big/small enough power to work with everything? I think I'd seen that the motors normally run on 24V, so if need be a can get another to meet any power requirements

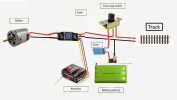

--I've seen on diagrams from a guide on conversion, Dummies Guide To Convert A Track Powered G Scale Locomotive To Rc Battery Powered and Getting started with battery power and radio control, that I'd need a switch and fuse, and wondered if their still needed if I can unplug the battery instead. I'd altered the diagram for what I think works for if I went for interchangeable power between track and battery. From a little bit of research, I think that's how that kind of switch works?

--I have no idea how a receiver would work, if at all, when connected to basic analog track power. I'd still want at least basic electric motor sounds when powered by the track if that's how it works.

--Somewhat related, but I'd read somewhere that it'd be best to get a voltage detector for the battery to tell me when it's getting low, as apparently LiPo batteries shouldn't be run empty.

Speakers:

--At least with this part, I know bigger is better. But are there certain kinds of speakers that are better than others?

--I'd be going with ESU branded speakers for consistancy, but with how many different sizes and shapes they have, it's all a bit overwhelming.

Thankfully these carriages have an abundance of space for all the things I'll need to put in them, so I've no shortage in that regard.

I've spent quite a while researching and compiling all the information I could, so hopefully this mostly covers everything I'm trying to do, so if I missed anything someone else may know of, or anything else I can add on to help with helping, could you please mention so. I'll try my best to reply to anything as soon as possible.

And if anyone in Australia, or more locally around Melbourne, knows of someone who does these conversions more professionally, that would be greatly appreciated. I would like to learn to do things like this myself, but going from no experience to this project, I've no clue how easy it is.

Thank you for taking the time to read, and I hope to receive some valuable advice to get my train converted.

This'll also be a pretty loaded post, but I want to try to get all the information I've researched in one go. So apologies for how much there'll be.

I will also say, I have zero experience with wiring and soldering, so will be learning how it all works as I go along.

My goal is to convert my LGB LCE 70600 from the original track power, to remote control and battery power with a sound card as well, so I can just unpack it on whatever layout, and just turn it on and control it wirelessly with a controller.

And if possible, make it interchangable between track/battery power, track power not needing to be wirelessly controlled.

The whole train consists of 8 cars, a powered car at each end, with 6 intermediate between.

So far the only thing I know for certain I'd have to get would be an ESU LokSound 5 XL sound card, as they have a sound file that I like.

My problems start with that I'm not sure what else I need to get, or how any of it works.

Transmitter/Receiver:

--I've been looking into Deltang/RCT for a transmitter/receiver, with the Tx20 transmitter looking to be better suited for my needs, but then not knowing which receiver of the 2 they offer to go with. I'd only be needing a small amount of extra sounds, such as horn, station announcements etc, so the

--The Rx102 (The RCT-Rx102 receiver) seems the more basic, and the wiring diagram they show on their page looks like what I think I;m going for. And the Rx65c (The RCT-Rx65b receiver) looks like it has more options for connecting to a sound card, and has a built-in esc, which sounds like a good thing?

--I'd also seen ESU has their own controller, the Mobile Control II, but they are horribly expensive, and I've got no clue what kind of receiver they work with.

Wiring:

--Given I've not done anything of the sort before, I've got no clue as to what wires go where, or how things work electrically.

--To go the cheaper route, I'll most likely go with the main workings at one end, i.e. battery, receiver, sound card, speakers, and have wires go through the train to the other end to power the other motor/speakers/directional light.

--I'd seen on another post on here that someone had used mini DIN plugs/sockets at each carriage connection to get them through and still be able to take the train apart for storage. Though I'd heard somewhere that having a long cable between power and motor has some kind of effect with resistance/power loss? Again, I have zero clue with electrics.

--With that, do different coloured wires do different things, or are they just to differentiate between uses? And if so, are there common colours for certain uses to stick to, or just go with whatever and remember what does what yourself?

Sound Card:

--The ESU LokSound 5 XL, from what I can tell, would best suit how I want it to sound. Apart from that, and from what little I've found, I wouldn't know as to how to it works. Such as what wires would go where? A diagram of what the terminals all do I found just ends up confusing me. Do wires for directional lights need to go straight from the receiver to the lights, or do they go through the decoder first? Do wires go to the from the receiver to the decoder and then to the motor?

--I'd be getting the ESU LokProgrammer to go with it so I could put on my own sound file from their site.

--From what I've seen, it looks like you just set certain terminals to a sound, and the receiver triggers it if a wire connects to it and is powered? I have yet to learn how increasing the speed of the train changes how the sound of the engine builds up, but I assume it detects power increase for the motor wires? Or axle rotation?

Battery:

--I've already got a good LiPo battery that I use for my R/C rock crawler car, so I'd hope to use that for this as well preferably.

--It's a 7.4V 5Amp LiPo battery, and have a fancy charger for it already. Would this be a big/small enough power to work with everything? I think I'd seen that the motors normally run on 24V, so if need be a can get another to meet any power requirements

--I've seen on diagrams from a guide on conversion, Dummies Guide To Convert A Track Powered G Scale Locomotive To Rc Battery Powered and Getting started with battery power and radio control, that I'd need a switch and fuse, and wondered if their still needed if I can unplug the battery instead. I'd altered the diagram for what I think works for if I went for interchangeable power between track and battery. From a little bit of research, I think that's how that kind of switch works?

--I have no idea how a receiver would work, if at all, when connected to basic analog track power. I'd still want at least basic electric motor sounds when powered by the track if that's how it works.

--Somewhat related, but I'd read somewhere that it'd be best to get a voltage detector for the battery to tell me when it's getting low, as apparently LiPo batteries shouldn't be run empty.

Speakers:

--At least with this part, I know bigger is better. But are there certain kinds of speakers that are better than others?

--I'd be going with ESU branded speakers for consistancy, but with how many different sizes and shapes they have, it's all a bit overwhelming.

Thankfully these carriages have an abundance of space for all the things I'll need to put in them, so I've no shortage in that regard.

I've spent quite a while researching and compiling all the information I could, so hopefully this mostly covers everything I'm trying to do, so if I missed anything someone else may know of, or anything else I can add on to help with helping, could you please mention so. I'll try my best to reply to anything as soon as possible.

And if anyone in Australia, or more locally around Melbourne, knows of someone who does these conversions more professionally, that would be greatly appreciated. I would like to learn to do things like this myself, but going from no experience to this project, I've no clue how easy it is.

Thank you for taking the time to read, and I hope to receive some valuable advice to get my train converted.