- 14 Jun 2011

- 4,063

- 947

- Best answers

- 0

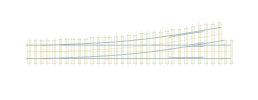

I have been messing around with my new 3D printer and have printed these.

Printed in PLA+ they are one of many sets that are planned to be used when I finally get around to build my storage tracks inside the shed.

Only thing I can fault is that the flange depth at the frog is to shallow but that can be overcome with a bit of filing.

www.thingiverse.com

www.thingiverse.com

Going to team them with some of these

www.thingiverse.com

www.thingiverse.com

First up I might put this set outside on the layout and stress test them to see if any wagon or loco doesn't like them and how they wear.

Printed in PLA+ they are one of many sets that are planned to be used when I finally get around to build my storage tracks inside the shed.

Only thing I can fault is that the flange depth at the frog is to shallow but that can be overcome with a bit of filing.

45mm Turnout for Garden Railway Track System by arockStone

After att total rebuild off my Turnout 32mm it's finally here. Turnout for 45mm gauge tracks (SM45) common used in Garden railways (16mm and LGB scale). The turnout radius are 1150mm and a steeper radius curved track is included . I will be very glad if you publish pictures off your printings.

Going to team them with some of these

Turnout Lever for Garden Railway System by arockStone

This is a Lever to maneuver your Turnouts on your Garden railway

First up I might put this set outside on the layout and stress test them to see if any wagon or loco doesn't like them and how they wear.

Last edited:

-

4

- Show all