ARIA31

Registered

Hello all,

The story started with this picture made by a G scale railroader "Vibrocop" on another french forum dedicated to US trains.

I was willing to have such a transfo on my indoor railroad.

This transfo is quite big : 250 x 172 x 100

I have a good friend Joël living close to my home and mastering very well his 3D printer.

Accordingly I asked to "Vibrocop" if he would send me the 3D files to get the same transfo printed by Joël.

Vibrocop immediately accepted and transferred the stl files.

However the parts were a little bit too big for the Joël printer.

So Joël who is mastering as well the Autodesk Fusion software cut the affected parts in 2 pieces.

Joël started the printing in PLA.

Was not an easy task as you can imagine, but at the end the parts are perfect.

Joël is not a large scale railroader , but was keen to finalize the transfo construction.

So he made the assembly , surface sanding, and finally air brush painting..

To make it short , the assembly and sanding were not easy tasks as well.

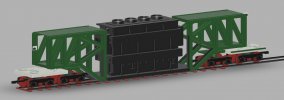

The transfo is now ready for delivery by train:

Comparison with the LGB transfo which is already quite big

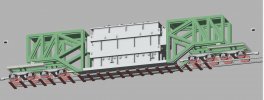

Here is the first video with the wagons I already have.

There is no existing wagon to carry this load.

The Usa trains depressed center flat cars are too small in length.

As you can see the transfo is very high so a new suitable transport wagon is needed.

That's another story to come........ stay tuned !!!

The story started with this picture made by a G scale railroader "Vibrocop" on another french forum dedicated to US trains.

I was willing to have such a transfo on my indoor railroad.

This transfo is quite big : 250 x 172 x 100

I have a good friend Joël living close to my home and mastering very well his 3D printer.

Accordingly I asked to "Vibrocop" if he would send me the 3D files to get the same transfo printed by Joël.

Vibrocop immediately accepted and transferred the stl files.

However the parts were a little bit too big for the Joël printer.

So Joël who is mastering as well the Autodesk Fusion software cut the affected parts in 2 pieces.

Joël started the printing in PLA.

Was not an easy task as you can imagine, but at the end the parts are perfect.

Joël is not a large scale railroader , but was keen to finalize the transfo construction.

So he made the assembly , surface sanding, and finally air brush painting..

To make it short , the assembly and sanding were not easy tasks as well.

The transfo is now ready for delivery by train:

Comparison with the LGB transfo which is already quite big

Here is the first video with the wagons I already have.

There is no existing wagon to carry this load.

The Usa trains depressed center flat cars are too small in length.

As you can see the transfo is very high so a new suitable transport wagon is needed.

That's another story to come........ stay tuned !!!