TempLayout

Registered

Hello all.

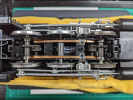

I've got a few Piko American Steam locos that all (some worse than others) make a weird chirping sound a the lower end of the RPM range. It's not much of a electronic hum or buzz (frequency), but more of a very quickly repeated mechanical squeak type of chirping. It's definitely based on the RPM of the shaft. In doing some maintenance recently I've pulled one of them entirely apart to give it a thorough cleaning/refurbishing. That model in particular wasn't running/looking too great after having been in storage for about 4 years or so. It is the Santa Fe Freight Train Starter Set #37104 0-6-0 loco which has the simpler running gear and no bearings. It is not the newer R/C Version. Years back I decided to go DCC and I bought and installed the Piko American Steam DCC Sound Kit and the recommended Visaton speaker for it. Overall it works great.

Just the other day, I cleaned up everything and tore down the whole motor block and cleaned out all the old grease and electrical contacts. I took out the motor and put just a tiny drop of R/C Electric motor oil that I've been using on R/C Cars for a while on the ends of the shaft on either side of the can. Then I hooked the motor up to some DC power and let it run a bit. It quieted down quite a but. Long story not quite as long, I built it all back up and when running it, the sound persists and it's pretty loud. I'm sure with the volume turned up it would be far less noticeable but it is absolutely present. I'm curious if it may have something to do with the frequencies in the Decoder CV settings or not. I don't think so. I'm pretty convinced it's a mechanical issue with the bearings or lack thereof (possibly brass bushings) on the motor shaft. My gut says it just needs more oil, but I REALLY don't want to put a bunch on oil on the motor... 100% spells trouble in my mind. I'm very in the "less is more" line of thinking. Maybe it's just the way it is?

My other Pikos make this same sound too and both of the following have ball bearing motor blocks:

Piko 38210 D&RGW Rio Grande 2-6-0 Mogul Steam #218 (Piko American Steam DCC/Sound added by me)

Piko 38141 B&O 0-6-0 Digital Starter Set #95 (Came with the Decoder stuff installed)

I have a camel back and another mogul that I haven't been able to get to recently that I'd like to check. Too much stuff out and they are tucked far away in a corner of storage.

On the other hand, my DC (non-DCC) LGB 2076 D DR Steam 0-4-0 I got for my 5th birthday that is nearly 40 years old, also was recently taken apart and built back up in the exact same care/style as I did the Piko and wow. That thing runs and slides along the rails as smooth/quiet as a well maintained high end sewing machine! And it's seen some hard use and multi decade storage cycles. The pikos run pretty well, they just make chirping sounds and I prefer they didn't. Mechanical squeaks like that tell me something's not right/done well. Who makes the motors for Piko? Can I buy a better one from some other supplier? It has to be a stock motor type/shape/style... just the shaft and worm gear might be the biggest hurdle.

I've got a few Piko American Steam locos that all (some worse than others) make a weird chirping sound a the lower end of the RPM range. It's not much of a electronic hum or buzz (frequency), but more of a very quickly repeated mechanical squeak type of chirping. It's definitely based on the RPM of the shaft. In doing some maintenance recently I've pulled one of them entirely apart to give it a thorough cleaning/refurbishing. That model in particular wasn't running/looking too great after having been in storage for about 4 years or so. It is the Santa Fe Freight Train Starter Set #37104 0-6-0 loco which has the simpler running gear and no bearings. It is not the newer R/C Version. Years back I decided to go DCC and I bought and installed the Piko American Steam DCC Sound Kit and the recommended Visaton speaker for it. Overall it works great.

Just the other day, I cleaned up everything and tore down the whole motor block and cleaned out all the old grease and electrical contacts. I took out the motor and put just a tiny drop of R/C Electric motor oil that I've been using on R/C Cars for a while on the ends of the shaft on either side of the can. Then I hooked the motor up to some DC power and let it run a bit. It quieted down quite a but. Long story not quite as long, I built it all back up and when running it, the sound persists and it's pretty loud. I'm sure with the volume turned up it would be far less noticeable but it is absolutely present. I'm curious if it may have something to do with the frequencies in the Decoder CV settings or not. I don't think so. I'm pretty convinced it's a mechanical issue with the bearings or lack thereof (possibly brass bushings) on the motor shaft. My gut says it just needs more oil, but I REALLY don't want to put a bunch on oil on the motor... 100% spells trouble in my mind. I'm very in the "less is more" line of thinking. Maybe it's just the way it is?

My other Pikos make this same sound too and both of the following have ball bearing motor blocks:

Piko 38210 D&RGW Rio Grande 2-6-0 Mogul Steam #218 (Piko American Steam DCC/Sound added by me)

Piko 38141 B&O 0-6-0 Digital Starter Set #95 (Came with the Decoder stuff installed)

I have a camel back and another mogul that I haven't been able to get to recently that I'd like to check. Too much stuff out and they are tucked far away in a corner of storage.

On the other hand, my DC (non-DCC) LGB 2076 D DR Steam 0-4-0 I got for my 5th birthday that is nearly 40 years old, also was recently taken apart and built back up in the exact same care/style as I did the Piko and wow. That thing runs and slides along the rails as smooth/quiet as a well maintained high end sewing machine! And it's seen some hard use and multi decade storage cycles. The pikos run pretty well, they just make chirping sounds and I prefer they didn't. Mechanical squeaks like that tell me something's not right/done well. Who makes the motors for Piko? Can I buy a better one from some other supplier? It has to be a stock motor type/shape/style... just the shaft and worm gear might be the biggest hurdle.