3 minutes of fame

3d printing, electronics and trams

Hello, sorry it's been a while. My G45 garden layout took a back seat following some issues with rot, so I dismantled it pending rebuild.

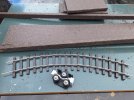

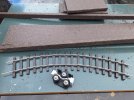

So this weekend I got the chance to start the rebuild. I'm using the existing fence posts, as they're all in good condition, while the 19mm plywood track base has been replaced with Filcris recycled plastic "wood". This consists of 50mm x 30mm runners, with 19mm planking. This gives enough flexibility to withstand expansion and damage, while retaining a base level within 2mm over the whole circuit.

To bend the Cliff Barker stainless track into permanent curves - rather than just pinning the flexible lengths in place, I made myself a rail bender from some parts from a defunct 3D printer, and a 3d printed insert. It works very well, and can be easily adjusted.

While picking up some bits from Wickes, I saw these decking modules on special offer at £12 for 4.They are made of a quality flexible plastic, and screwed to the plastic backing frame. Perfect for platforms or bridge decks!

More pictures as track laying continues..

So this weekend I got the chance to start the rebuild. I'm using the existing fence posts, as they're all in good condition, while the 19mm plywood track base has been replaced with Filcris recycled plastic "wood". This consists of 50mm x 30mm runners, with 19mm planking. This gives enough flexibility to withstand expansion and damage, while retaining a base level within 2mm over the whole circuit.

To bend the Cliff Barker stainless track into permanent curves - rather than just pinning the flexible lengths in place, I made myself a rail bender from some parts from a defunct 3D printer, and a 3d printed insert. It works very well, and can be easily adjusted.

While picking up some bits from Wickes, I saw these decking modules on special offer at £12 for 4.They are made of a quality flexible plastic, and screwed to the plastic backing frame. Perfect for platforms or bridge decks!

More pictures as track laying continues..