bensch_55

Registered

Hello everyone,

as you might know from my new members post, I am currently working on a model of the ÖBB 399 (NÖLB "Mh"). I want to document and share some of my progress here with you.

The major objective of this project is to make everything 3D print-friendly as well as easy to assemble, similar to LGB models. In the long run I would also consider offering this as a full set to purchase, should there be any demand for it.

Then there are the targets this model has to fullfill:

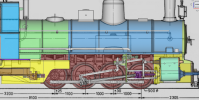

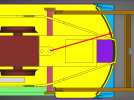

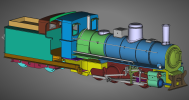

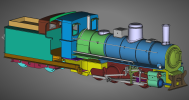

This is the current status in CAD:

(Some off the shelf parts are depicted as placeholders or not in the model at all)

As you can see, the major components are mostly finished. The main focus right now is on the valve gear which is still missing some details.

If you have any questions or see some room for improvements, please let me know

Wish you all a great day,

Ben

as you might know from my new members post, I am currently working on a model of the ÖBB 399 (NÖLB "Mh"). I want to document and share some of my progress here with you.

The major objective of this project is to make everything 3D print-friendly as well as easy to assemble, similar to LGB models. In the long run I would also consider offering this as a full set to purchase, should there be any demand for it.

Then there are the targets this model has to fullfill:

- Min. Radii R1

- Sound

- Smoke (incl. cylinder smoke)

- Utilizing already existing LGB running gear

- Lights (incl. cabin)

This is the current status in CAD:

(Some off the shelf parts are depicted as placeholders or not in the model at all)

As you can see, the major components are mostly finished. The main focus right now is on the valve gear which is still missing some details.

If you have any questions or see some room for improvements, please let me know

Wish you all a great day,

Ben