DickyC

(BZB Mountain Railway)

12: SEATING.

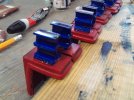

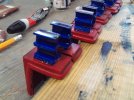

Seating back in, needed to add hight to each seat so used some plastikard ( pre formed "I" beams) they were not going to be seen so didnt need to be neat but only a light colour, Itwas MEK bonded and then superglued to the 3d printed seats, Loctite superglue was then used to attached to the floor of the frame.

Layers of seats go in and also people ! This is above the passenger viewing area at the front, I had to stenghten this area and build up after I dropped the front ! so it was harder to get items in. I also put in a dashboard and cup holder decal.

THIS IS ME ! as an 9 year old kid riding at the front in the 80s, all of the front to myself.

I then started on the lighting within the coach. It has lights at the front, in the roof and in the dials of the cab. A 6v voltage reducer from Mxion used in the roof lights

original LGB restaurant roof fitting reused, recycled and new LED lights.

New holes drilled for fitting old LGB hoses and pipes

Toggle switch's to turn lights on/off placed underneath. This will be connected to another coach where the batteries will be held (later project). I also had to adapt the coach corridors connectors as the back was much smaller now than the original. Doors, Wheelsets and extras all replaced,

Lighting testing

Seating back in, needed to add hight to each seat so used some plastikard ( pre formed "I" beams) they were not going to be seen so didnt need to be neat but only a light colour, Itwas MEK bonded and then superglued to the 3d printed seats, Loctite superglue was then used to attached to the floor of the frame.

Layers of seats go in and also people ! This is above the passenger viewing area at the front, I had to stenghten this area and build up after I dropped the front ! so it was harder to get items in. I also put in a dashboard and cup holder decal.

THIS IS ME ! as an 9 year old kid riding at the front in the 80s, all of the front to myself.

I then started on the lighting within the coach. It has lights at the front, in the roof and in the dials of the cab. A 6v voltage reducer from Mxion used in the roof lights

original LGB restaurant roof fitting reused, recycled and new LED lights.

New holes drilled for fitting old LGB hoses and pipes

Toggle switch's to turn lights on/off placed underneath. This will be connected to another coach where the batteries will be held (later project). I also had to adapt the coach corridors connectors as the back was much smaller now than the original. Doors, Wheelsets and extras all replaced,

Lighting testing