ThomasDadDurham

Really Useful Engine

Im wanting my passing loops to use analogue automation, using RRConcepts Stationmaster system. The issue here is that two of my 5 locos are over twice as fast, if not three times as fast, as all the others (Diesel and Toby). They're all cleaned, and Ive asked other owners of the Thomas Large Scale Range and the consensus is - they are all radically different. That aligns with my opening them up. Same motors, but very different gearing, and age is also likely a factor with all of mine being 2nd hand, bar Diesel and Percy).

The alternating trains setups needs them roughly the same speed. At present, enough power to get James or Thomas up my incline with a train, means Toby or Diesel races round so fast they fly off on the first corner.

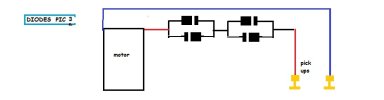

Ive been told 'add a string of diodes' as each diode gives a slight voltage drop. But I dread spending days soldering and unsoldering to try and dial in Diesel and Tobys speeds to match James/Thomas/Percy.

My question is, cant I add some sort of adjustable thing, some sort of speed controller, to the loco? Its confusing me because that would be like a second speed controller in line with the first (my controls are Gaugemaster GMC-10LGB's, fitted with PWM to Linear Converters from GScale Graphics as it was recommended to protect my locos which have soundcards.) and electronically, I have no idea what issues that would cause??

(Before the cries of 'go DCC', I really dont want to switch to DCC, because even then, I cant simply do 'alternating trains on a station stop passing loop', short of it seems, a degree in programming and making completely bespoke circuits. I just want an off-the-shelf solution hence the Stationmaster.)

The alternating trains setups needs them roughly the same speed. At present, enough power to get James or Thomas up my incline with a train, means Toby or Diesel races round so fast they fly off on the first corner.

Ive been told 'add a string of diodes' as each diode gives a slight voltage drop. But I dread spending days soldering and unsoldering to try and dial in Diesel and Tobys speeds to match James/Thomas/Percy.

My question is, cant I add some sort of adjustable thing, some sort of speed controller, to the loco? Its confusing me because that would be like a second speed controller in line with the first (my controls are Gaugemaster GMC-10LGB's, fitted with PWM to Linear Converters from GScale Graphics as it was recommended to protect my locos which have soundcards.) and electronically, I have no idea what issues that would cause??

(Before the cries of 'go DCC', I really dont want to switch to DCC, because even then, I cant simply do 'alternating trains on a station stop passing loop', short of it seems, a degree in programming and making completely bespoke circuits. I just want an off-the-shelf solution hence the Stationmaster.)