Yes, its very easy to assume the worse. How many car mechanics have located the source of "a nasty rattling from the engine/gear box" down to a loose penny in the glove box?Once you have done all that, and checked their performance, then think a

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to slow a loco that is a LOT faster than all my others. Electronics experts help please!

- Thread starter ThomasDadDurham

- Start date

ThomasDadDurham

Really Useful Engine

I didnt want to write war and peace on my initial post, but yes, I have had them completely apart, cleaned all contacts, popped open the motor on James and cleaned debris, checked everything spins and turns freely where it should, cleaned the wheels (I do this after every running session).Ah now you say. OK, well used 2nd hand items that may be well worn and mucked about with. This could have an effect on performance, and not consistently.

"Get around the garden". How big is your garden and how long is a trip around ? What are you using as a power source and controller. Do you use any power bosting cables ? What do you use to connect your track sections, joiner or clamps ? Was that bought 2nd hand too ? Yes, measure the voltage at various points around the track. Is it fairly constant or does it drop off the further away you get from where you power is inputted or at different points ?

The purpose of ballasting a loco, common LGB practice and others, is to provide adhesion to the wheels of what is a light plastic contraption without. No adhesion no pulling power. The more you hang off the loco the slower it will go (wheel slip). Goes for each of your locos. Gradients will just make it worse. Make sure all locos are complete in that department.

I'd give all the locos mechanisms a full strip, clean, inspection. Check for damaged, slipping gears and drives to driven axles. Anything binding ? Look for fluff, hair, etc if they were once used indoors. Messes with the tolerances between axles and bearings. Motors, if old, probably have a lot of carbon debris and clag on and in-between the commutator sectors that needs cleaning. Clean surface, backs and check condition of wheels, bit of smoke oil helps. Clean all electrical contacts, especially the ones contacting backs of wheels. Motors probably over oiled by a previous owner.

Once you have done all that, and checked their performance, then think about diodes. Max

The garden is around 60m of track, two parralel tracks. The worst part is the two inclines which were designed to be no steeper than 1 in 30, but i miscalculated thinking my garden was perfectly flat when it actually slopes up about 15-20cm towards the back corner, but when you're talking a 10-12 metre long incline along the length of the back of the garden, up to a raised area and viaduct ~30cm high (28cm to the 'trackbed') it cant be worse than 1 in 20 - at the absolute worst, thats assuming the worst case of every measurement- (no way am I rebuilding it as it took me two whole summers.) Short of expensive laser equipment Im never going to know the gradient for sure.

It uses clamps, the track is mostly good quality 2nd hand 120cm straights, with new curves, kept clean and rubbed down before each run, it has feeder cables every 5-6 metres. I even went and put the steepest problem part on a seperate third controller so I can increase the power on that section. They all get up it no problem, its just a case of making sure the rest of the circuit, which includes the opposite downwards incline, is ran on less power so they arent going unrealistically fast. When I didnt have the steepest section on a seperate controller, it wasnt wheelslip that was an issue, it was just that they slowed down so much it was visually boring.

All three power controllers are Gaugemaster GMC-10LGB5F. Probably overkill, BUT they were available to me so Ive gone with them.

James isnt pulling longer trains - station passing loop length limits them all to six trucks or 3 or 4 carriages. (Thomas trucks are ~25cm ish, carriages are ~55cm ish)

(Forget I said anything about the LGB Locos, they arent the issue or anything to with this thread at all, having sourced pictures of the original weights the LCE should have had Im confident I can craft replacements in Lead or steel.)

We're purely focused on why James is so slow, needing almost full power at the top of the dial, but Toby and Diesel are lightning fast and responding to the mildest adjustment at the lower end of the dial by almost throwing themself off the track, while Thomas and Percy are just normal and behave as you'd expect, with speeds ranging from creep to fast across the range of the dial. It isnt track power, it isnt cleaning.

It -may- just be age, but Ive asked on Thomas specific groups and people confirm that there are radically different speeds across the range. Other owners are saying they have two identical locos, of identical age and condition, with different speeds (ie they used two Percys to modigy into Bill & Ben, or two Diesels to modify into Arry and Bert, and they have different speeds).

This is a long running saga, from my perspective it is often difficult to get 2 trains running very much the same even same loco types, irritating but there it is.Im wanting my passing loops to use analogue automation, using RRConcepts Stationmaster system. The issue here is that two of my 5 locos are over twice as fast, if not three times as fast, as all the others (Diesel and Toby). They're all cleaned, and Ive asked other owners of the Thomas Large Scale Range and the consensus is - they are all radically different. That aligns with my opening them up. Same motors, but very different gearing, and age is also likely a factor with all of mine being 2nd hand, bar Diesel and Percy).

The alternating trains setups needs them roughly the same speed. At present, enough power to get James or Thomas up my incline with a train, means Toby or Diesel races round so fast they fly off on the first corner.

Ive been told 'add a string of diodes' as each diode gives a slight voltage drop. But I dread spending days soldering and unsoldering to try and dial in Diesel and Tobys speeds to match James/Thomas/Percy.

My question is, cant I add some sort of adjustable thing, some sort of speed controller, to the loco? Its confusing me because that would be like a second speed controller in line with the first (my controls are Gaugemaster GMC-10LGB's, fitted with PWM to Linear Converters from GScale Graphics as it was recommended to protect my locos which have soundcards.) and electronically, I have no idea what issues that would cause??

(Before the cries of 'go DCC', I really dont want to switch to DCC, because even then, I cant simply do 'alternating trains on a station stop passing loop', short of it seems, a degree in programming and making completely bespoke circuits. I just want an off-the-shelf solution hence the Stationmaster.)

Have you thought about using the LGB EPL system? This works on sensors (changing in effect relays that can be the auxiliary switch on a point. Thus differing speeds of locomotive matter not, one will wait till the other one us tucked nicely in the loop before it sets off at its possibly rocket speed.

Simple to setup, no degree in computer Science degree required just the ability to adapt the system to your needs. Below is my variation using the system, I was working towards the ability to have a train going the other way as well stopping and passing in loops but never got to that, but it is entirely possible. You cant see it too well but the white bit in the middle just to the right of the yellow box is a lump of melamine that has LGB point motors with auxiliary switches to act as the relays. I have used this setup as a portable one to take to friends gardens in the past.

.

maxi-model

UK/US/ROW steam narrow gauge railways 1:1

I didnt want to write war and peace on my initial post, but yes, I have had them completely apart, cleaned all contacts, popped open the motor on James and cleaned debris, checked everything spins and turns freely where it should, cleaned the wheels (I do this after every running session).

The garden is around 60m of track, two parralel tracks. The worst part is the two inclines which were designed to be no steeper than 1 in 30, but i miscalculated thinking my garden was perfectly flat when it actually slopes up about 15-20cm towards the back corner, but when you're talking a 10-12 metre long incline along the length of the back of the garden, up to a raised area and viaduct ~30cm high (28cm to the 'trackbed') it cant be worse than 1 in 20 - at the absolute worst, thats assuming the worst case of every measurement- (no way am I rebuilding it as it took me two whole summers.) Short of expensive laser equipment Im never going to know the gradient for sure.

It uses clamps, the track is mostly good quality 2nd hand 120cm straights, with new curves, kept clean and rubbed down before each run, it has feeder cables every 5-6 metres. I even went and put the steepest problem part on a seperate third controller so I can increase the power on that section. They all get up it no problem, its just a case of making sure the rest of the circuit, which includes the opposite downwards incline, is ran on less power so they arent going unrealistically fast. When I didnt have the steepest section on a seperate controller, it wasnt wheelslip that was an issue, it was just that they slowed down so much it was visually boring.

All three power controllers are Gaugemaster GMC-10LGB5F. Probably overkill, BUT they were available to me so Ive gone with them.

James isnt pulling longer trains - station passing loop length limits them all to six trucks or 3 or 4 carriages. (Thomas trucks are ~25cm ish, carriages are ~55cm ish)

(Forget I said anything about the LGB Locos, they arent the issue or anything to with this thread at all, having sourced pictures of the original weights the LCE should have had Im confident I can craft replacements in Lead or steel.)

We're purely focused on why James is so slow, needing almost full power at the top of the dial, but Toby and Diesel are lightning fast and responding to the mildest adjustment at the lower end of the dial by almost throwing themself off the track, while Thomas and Percy are just normal and behave as you'd expect, with speeds ranging from creep to fast across the range of the dial. It isnt track power, it isnt cleaning.

It -may- just be age, but Ive asked on Thomas specific groups and people confirm that there are radically different speeds across the range. Other owners are saying they have two identical locos, of identical age and condition, with different speeds (ie they used two Percys to modigy into Bill & Ben, or two Diesels to modify into Arry and Bert, and they have different speeds).

Don't talk to me about inclines, I ended up building up the front of my garden to get a partial correction, but it does save on my tired old back and knees. Sounds like you have it all covered and have isolated all the variables - the apparent inconsistencies in performance between the various TTE locos. Does sound strange that a group of products you would expect to have similar performance don't. That and the comments on user TTE forums to back it up. Seems to point to good old Oriental QC issues or an insidious plot to get the kids racing their steeds, resulting in requests for, "I want a faster one, just like Timmy's daddy/grandpa !"

I think you should call the Fat Controller in to give those pesky locos a good talking to and lay down the law. "Behave ! You don't want to end up like Henry, do you ?" If that fails, seems like the diodes trick is leading the race here. I have solved my speed differentials, all my locos are radio controlled and battery powered now. I control the locos, they don't control me. You'd think the Chinese had got that worked out. But then that can get a tad expensive and then you have to manage the charging and stop the kids fighting over the transmitters and..........Oh forget it

ThomasDadDurham

Really Useful Engine

He has the same 'guts' as Thomas, he is slightly bigger of course but its all big hollow plastic parts, so the weight difference is negligible, you'd expect some speed difference but not these speeding bullet vs tortoise levels.Isn't James a heavier engine, complete with tender? Have you checked the tender is running freely?

This is essentially the same thing as the RRConcepts. The main issue isnt automation, but that I dont want to have to stand permanent sentinal at the controls, turning the speed controller up or down as different trains pull out of the station, so the slow ones make the inclines while the fast ones dont skip the tracks.This is a long running saga, from my perspective it is often difficult to get 2 trains running very much the same even same loco types, irritating but there it is.

Have you thought about using the LGB EPL system? This works on sensors (changing in effect relays that can be the auxiliary switch on a point. Thus differing speeds of locomotive matter not, one will wait till the other one us tucked nicely in the loop before it sets off at its possibly rocket speed.

Simple to setup, no degree in computer Science degree required just the ability to adapt the system to your needs. Below is my variation using the system, I was working towards the ability to have a train going the other way as well stopping and passing in loops but never got to that, but it is entirely possible. You cant see it too well but the white bit in the middle just to the right of the yellow box is a lump of melamine that has LGB point motors with auxiliary switches to act as the relays. I have used this setup as a portable one to take to friends gardens in the past.

.

The speed difference is so extreme you absolutely cannot find a happy middle ground, so yes the different speeds of the locos matter very much because the issue isnt automation, the issue is I need them both to get round at the same speed-controller-setting without slow locos stalling or fast locos jumping the tracks.

So where Im at now as I need to find a free weekday (almost impossible) to trek up to Whitley Bay and ESR Electrical, from Durham to pickup diodes (and perhaps a multimeter because customer loyalty, when they've been so helpful / im deeply distrustful of electronics from Amazon, having past bought innacurate scales, an innacurate clock and an innacurate thermometer haha. Perhaps I will grab bits off there but I always like getting the advice from them before I start soldering stuff in.)

I have motors arriving for James, which is worth a shot, and means I have spares if I accidentally fry something.

Im slammed with work right now and having to do 3pm school pickups rather than crack on with it, so it may well be between Christmas and New Year when I can sit down with the rolling road, Q-tips and Isopropyl, and a soldering iron and spend a couple of days trying to dial the speed in.

What Im sad about is they'll only run in one direction now - can you not do two chains of diodes, with a single diode in reverse in parralel? Or am I misunderstanding how they work here.

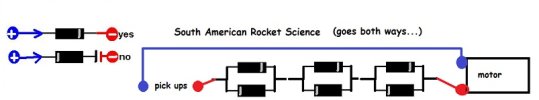

The diode 'ladder' is bi-directional, so will work for forwards / backwards..What Im sad about is they'll only run in one direction now - can you not do two chains of diodes, with a single diode in reverse in parralel? Or am I misunderstanding how they work here.

It is the speed controllers others suggested, that are polarity sensitive.

PhilP.

korm kormsen

Registered

ThomasDadDurham

Really Useful Engine

AHA! Right, when I see it like that it makes more sense!