AMuller396

Registered

Hi,

I recently got hands on this G Scale turntable.

I’m trying to test and see if it works but am having a bit of trouble due to my “inept” ability in electronics and anything electrical.

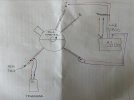

The instructions provided above shows how to connect it all together.

I know X1 and X2 should be connected to 20v AC which I have connected to LGB 50111.

X3-X6 should be connected to the wiring for the included control panel.

However, the cable for the control panel has 6 cables with X4 X5 X6 has yellow red and black inserted respectively. That leaves me with X3. There are 3 cables not attached orange brown and one with no jacket.

Anyone know which cable should go to what?

If I go with the 51800 it says to hook it up to a max 1amp AC transformer, so that seems my 50111 would be out of the picture?

The instructions for 51800 depicted above shows X3 and X4 to the far left of 51800 but that’s the input for the power on 51800 depicted with symbol 1*2 or 3*4 (LGB AC or dc). If that’s what they want how do I connect that 51800 to a 1 amp AC transformer?

Does anyone know if this item is suitable for outdoors year round? Southern California weather.

Also, If I decide to hook this up as a digital hook up what does one need to do?

Any other tips you might have for those that already have this item?

Thank you very much and I apologize if this was very trivial.

Andrew

I recently got hands on this G Scale turntable.

I’m trying to test and see if it works but am having a bit of trouble due to my “inept” ability in electronics and anything electrical.

The instructions provided above shows how to connect it all together.

I know X1 and X2 should be connected to 20v AC which I have connected to LGB 50111.

X3-X6 should be connected to the wiring for the included control panel.

However, the cable for the control panel has 6 cables with X4 X5 X6 has yellow red and black inserted respectively. That leaves me with X3. There are 3 cables not attached orange brown and one with no jacket.

Anyone know which cable should go to what?

If I go with the 51800 it says to hook it up to a max 1amp AC transformer, so that seems my 50111 would be out of the picture?

The instructions for 51800 depicted above shows X3 and X4 to the far left of 51800 but that’s the input for the power on 51800 depicted with symbol 1*2 or 3*4 (LGB AC or dc). If that’s what they want how do I connect that 51800 to a 1 amp AC transformer?

Does anyone know if this item is suitable for outdoors year round? Southern California weather.

Also, If I decide to hook this up as a digital hook up what does one need to do?

Any other tips you might have for those that already have this item?

Thank you very much and I apologize if this was very trivial.

Andrew