John Carmichael

Registered

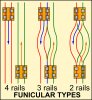

This is a rare two rail G-Scale Model Funicular with the ingenious and revolutionary ABT Passing switch. (the only railroad switch without moving parts!) It took seven months to design and build. See video of the first full system test here:

I moved it to my garden railway for permanent installation where I'll build a mountain around it. My funicular features automated station stops, delay, and reverse- all programmable. Speed is adjustable with a throttle. It also has an automatic warning bell just like the real ones, and extensive cabin and structural lighting. Controls are conveniently located outside of the rear of the Gear Room. Everything is weather resistant for outdoor use. The track slopes upwards at 30 degrees and is 72 inches long. I created the track and passing switch using LGB brass Flex track.

I believe this is the first G-Scale fully functional garden funicular railway in the United States with the ABT Passing Switch.

See ABT Switch Info: Abt Switch - Giessbach

And see this VERY interesting article: Giessbach Funicular.pdf (2.1 MiB)

To make a fully functional G-Scale model I had to teach myself everything about it since there is almost no information on modeling a funicular on the internet or in railroad magazines. Everything, including the crazy tracks, had to be designed by just using old photographs of real funiculars. It is the biggest railroading challenge I have ever undertaken. Precision in all parts of the design and construction was imperative. The split-level cars had to stop exactly in line with the boarding platforms. The cars had to travel at 3 inches/sec. so I had to teach myself all about gears and gear ratios and how to do the calculations knowing the motor's RPM. Difficult but lots of fun!

I’m making the full design drawings, electrical diagrams and construction photos available to everybody hoping that more will be built. This way, future modelers won’t suffer the learning pains and design errors I had to solve teaching myself how to make it. See here: G-Scale Funicular Garden Railway

My Funicular was inspired in part by a G-Scale demonstration model of the Horseshoe Curve funicular that was made in Barcelona Spain. I don’t know the maker’s name. Although his model is a little “rough around the edges”, it proved to me that an ABT Passing Switch was possible on a G-Scale track. I took his idea and made several improvements.

My thanks go out to the man in Barcelona and to Mr. Steve Worack, the person who designed and sold me the Circuitron AR-2 auto reverse & delay controller. His helpful connection advice was critical to the success of the project. It works perfectly. Thank you Steve.

If anybody has any questions, just ask.

Good luck with your funiculars,

John Carmichael

Tucson Arizona

email: jlcarmichael@comcast.net

I moved it to my garden railway for permanent installation where I'll build a mountain around it. My funicular features automated station stops, delay, and reverse- all programmable. Speed is adjustable with a throttle. It also has an automatic warning bell just like the real ones, and extensive cabin and structural lighting. Controls are conveniently located outside of the rear of the Gear Room. Everything is weather resistant for outdoor use. The track slopes upwards at 30 degrees and is 72 inches long. I created the track and passing switch using LGB brass Flex track.

I believe this is the first G-Scale fully functional garden funicular railway in the United States with the ABT Passing Switch.

See ABT Switch Info: Abt Switch - Giessbach

And see this VERY interesting article: Giessbach Funicular.pdf (2.1 MiB)

To make a fully functional G-Scale model I had to teach myself everything about it since there is almost no information on modeling a funicular on the internet or in railroad magazines. Everything, including the crazy tracks, had to be designed by just using old photographs of real funiculars. It is the biggest railroading challenge I have ever undertaken. Precision in all parts of the design and construction was imperative. The split-level cars had to stop exactly in line with the boarding platforms. The cars had to travel at 3 inches/sec. so I had to teach myself all about gears and gear ratios and how to do the calculations knowing the motor's RPM. Difficult but lots of fun!

I’m making the full design drawings, electrical diagrams and construction photos available to everybody hoping that more will be built. This way, future modelers won’t suffer the learning pains and design errors I had to solve teaching myself how to make it. See here: G-Scale Funicular Garden Railway

My Funicular was inspired in part by a G-Scale demonstration model of the Horseshoe Curve funicular that was made in Barcelona Spain. I don’t know the maker’s name. Although his model is a little “rough around the edges”, it proved to me that an ABT Passing Switch was possible on a G-Scale track. I took his idea and made several improvements.

My thanks go out to the man in Barcelona and to Mr. Steve Worack, the person who designed and sold me the Circuitron AR-2 auto reverse & delay controller. His helpful connection advice was critical to the success of the project. It works perfectly. Thank you Steve.

If anybody has any questions, just ask.

Good luck with your funiculars,

John Carmichael

Tucson Arizona

email: jlcarmichael@comcast.net

Last edited: