DannyTheElfman

Registered

Hey everyone,

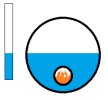

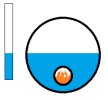

I'm sorry but I have a really dumb question. What is the correct way to read a sight glass on an Accucraft Loco? On my Countess the sight glass sits higher up than the boiler. I've drawn a diagram below to illustrate. But in the example the boiler is half full, but the water in the glass looks less than a third full. Is this correct or would the sight glass always mirror what is happening in the boiler, even if they sit at different heights?

You can see here the the boiler sits below the top of the sight glass. So presumably even if the boiler were full the glass would only read about 3/4?

I understand the sight glasses are actually pretty poor even at the best of times. Mine is definitely doing it's job, the longer I use the loco the more the water goes down, and a top up increases the water level in the glass. So it's definitely doing something correctly. I just don't know how to read it correctly.

Many thanks

Dan

I'm sorry but I have a really dumb question. What is the correct way to read a sight glass on an Accucraft Loco? On my Countess the sight glass sits higher up than the boiler. I've drawn a diagram below to illustrate. But in the example the boiler is half full, but the water in the glass looks less than a third full. Is this correct or would the sight glass always mirror what is happening in the boiler, even if they sit at different heights?

You can see here the the boiler sits below the top of the sight glass. So presumably even if the boiler were full the glass would only read about 3/4?

I understand the sight glasses are actually pretty poor even at the best of times. Mine is definitely doing it's job, the longer I use the loco the more the water goes down, and a top up increases the water level in the glass. So it's definitely doing something correctly. I just don't know how to read it correctly.

Many thanks

Dan