i actully meant to say very small almost non-existant flanges

I am terrible sorry to say but, i agree with what others are stating, it will not work.

I did myself a lot of experiments with prototypical flanges and prototypical turnouts ect, every test/experiment was mostly failure.

I even let go of the whole idea of prototypical, it is just to small to get things running properly.

Needles to say the AA20 in 1:32 in nmra let alone proto is not even possible.

My experiments with printing with abs are great, including a turnout, once you go bigger (3way scissors crossover ect)you will probably encounter problems.

The 5way was a piece of art, until the temperature droped 10C.

Why probably: i use alu strip and not a code rail.

To get your costs down really, look at some of my topics, i had some really great success with wood and alu strip, total cost per 125 cm/4.1 ft of finished track....not even 1 euro.

1 euro 25 if you must buy the hard wood and the putty.

The filament is also pretty costly i could get 5-6 meters/5,5-6,5 yard of track from 1 kilo.

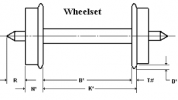

In proto a flange depth will be 0.8mm by 0.8mm i thought( iam quick with forgetting useless things), nmra standards will tell you something that

will work. since you have a 3d printer? i would recommend to print some boogies and some section of track.

In that section of curved track you want to make some safety rail and even mimic some frogs, go from proto typical measurements to nmra standard measurements.

Go from 4mm gap to 3mm to 2mm to proto.

Wheels with flanges from 4/0,16 to 3mm/0,12 to 2mm/0,8 to proto.

i suggest stick to 1mm/0,04 of flange thickness to start with.

This will save you a huge amount of time.

On @Greg Elmassian , website you will find all the info you need to develop your own track.

You will find a lot of standards there, incl his "last level" of what he is referring to as: our grandfather tracks (or something simulair, i can not recall exactly)

i could not find the pdf's very quick, but Greg will chime in.

Basically you need 2,5 to 3mm deep flanges and the gap between the safety rail and the stock rail would also be 3 up to 3.5 mm.

For my outside track (only for the biggest of the biggest loco's) i will even go to a 4mm gap(read,4.5mm).

Again sorry to say and i am the last one that wants to discourage or insult you, prototypical wont work.

Welcome to a world full of possible experiments, fun and learning

With best regards Igor