collectors

Registered

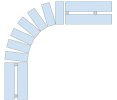

I want to run a 2 x R3 bend in parallel & believe normally a single track should have 1175mm centre of track radius. I want to run two tracks at 1075mm & 1275 giving a 200mm gap in between centres of the track. Can you see a problem or should this work.

The reason for asking is this is all on a raised track & wont have too much tolerance. Thanks

The reason for asking is this is all on a raised track & wont have too much tolerance. Thanks