kedwards

Caving, Garden Railways & more caving. Fan of TTTE

Apologies if this has been covered before. If so then please point me to the thread.

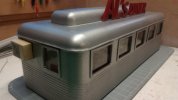

I've been making station buildings out of foamboard.

The dagger boards were too difficult to make so son in law designed and 3D printed them for me.

I'm so impressed that I have decided to buy a 3D printer to print out small items for my railway, but the printer market is a minefield for a numpty like me.

Do I go single or multi-colour? What size bed do I need? How much do I need to spend? Do I need an enclosure for printing with certain materials? I could go on.

What would your advice and recommendations be?

Thanks,

Keith

I've been making station buildings out of foamboard.

The dagger boards were too difficult to make so son in law designed and 3D printed them for me.

I'm so impressed that I have decided to buy a 3D printer to print out small items for my railway, but the printer market is a minefield for a numpty like me.

Do I go single or multi-colour? What size bed do I need? How much do I need to spend? Do I need an enclosure for printing with certain materials? I could go on.

What would your advice and recommendations be?

Thanks,

Keith