KeithT

Hillwalking, chickens and - err - garden railways.

It is always nice to get good customer service.

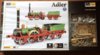

I am in the throes of building the Adler kit from OcCré but managed to break the wooden spokes in one of the drivers.

Last evening I sent an email to OcCré asking if they could provide a replacement for my ham fistedness, I was willing to pay inc p/p.

Early this morning I got an email thanking me for buying one of their kits and promising a replacement no charge all the way from Spain.

All to often we struggle to get reasonable service so it makes a pleasant change to get such a positive response.

I hasten to add that I have no connections with OcCré other than as a user of their kits.

I would dearly love to build their 2-3-1K Nord pacific but I fear that it is way beyond my skills - and eyesight.

I am in the throes of building the Adler kit from OcCré but managed to break the wooden spokes in one of the drivers.

Last evening I sent an email to OcCré asking if they could provide a replacement for my ham fistedness, I was willing to pay inc p/p.

Early this morning I got an email thanking me for buying one of their kits and promising a replacement no charge all the way from Spain.

All to often we struggle to get reasonable service so it makes a pleasant change to get such a positive response.

I hasten to add that I have no connections with OcCré other than as a user of their kits.

I would dearly love to build their 2-3-1K Nord pacific but I fear that it is way beyond my skills - and eyesight.