SevenOfDiamonds

Registered

Hello all

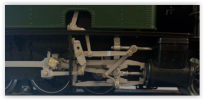

My LGB Heidi (20272) was running round the garden just fine but suddenly made a graunching sound and came to a stop. I recovered it to my workshop along with the single piece of silver-grey plastic I found alongside it.

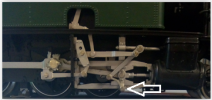

On closer inspection, the loose item was the part of the valve gear that sits above the running plate (one of which is shown circled in blue in the photo below). The equivalent one on the other side was also missing but, based on a rattling sound, I found it when I removed the loco body.

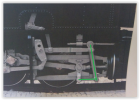

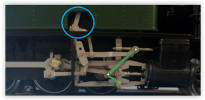

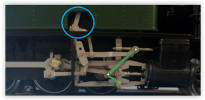

Armed with photographs from the LGB website (albeit of a 20274), I was able to re-seat the two pieces of plastic, and connect them onto the appropriate pins on the remaining valve gear. On one side of the loco, everything looked like the photo but, on the other, what should look like this (note the green parts) . . .

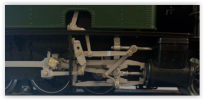

. . . was actually like this (facing the wrong way, and the "horizontal component" somewhat bent) . . .

My question is how do I return it to its correct orientation with the least amount of disassembly (and risk of further damage)?

Do we have any "valve gear experts" on here?

Cheers

David

My LGB Heidi (20272) was running round the garden just fine but suddenly made a graunching sound and came to a stop. I recovered it to my workshop along with the single piece of silver-grey plastic I found alongside it.

On closer inspection, the loose item was the part of the valve gear that sits above the running plate (one of which is shown circled in blue in the photo below). The equivalent one on the other side was also missing but, based on a rattling sound, I found it when I removed the loco body.

Armed with photographs from the LGB website (albeit of a 20274), I was able to re-seat the two pieces of plastic, and connect them onto the appropriate pins on the remaining valve gear. On one side of the loco, everything looked like the photo but, on the other, what should look like this (note the green parts) . . .

. . . was actually like this (facing the wrong way, and the "horizontal component" somewhat bent) . . .

My question is how do I return it to its correct orientation with the least amount of disassembly (and risk of further damage)?

Do we have any "valve gear experts" on here?

Cheers

David