Lez2000

Registered

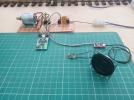

I'm after a bit of advice please. I'm looking for a reasonably priced decoder tester and so far have come across these:

Zimo MXTAPV and the ESU 53900.

There is quite a difference in price between them (Zimo almost double) but is the higher cost justified?

I'm assuming these are capable of testing any manufacturers decoders?

I would be very interested to hear your thoughts and experiences.

Thank you,

Les.

Zimo MXTAPV and the ESU 53900.

There is quite a difference in price between them (Zimo almost double) but is the higher cost justified?

I'm assuming these are capable of testing any manufacturers decoders?

I would be very interested to hear your thoughts and experiences.

Thank you,

Les.