Gerard

Registered

I had a lot of locs and wagons not in daily use stored in my cellar in the empty spaces of my wine store.

This meant I could not enjoy the looks of all that beautifull LGB stuff.

So i decided to build 3 exposition layers with about 7,5 m. long double track, mounted against the windows of my garden room.

The floor space along the walls of this room serve as my in house station.

While the centre of the room is in use as a music studio. So far this works fine.

Now I am planning to build a cogwheel track in front of the tracks to reach the 3 levels using a cogwheel locomotive.

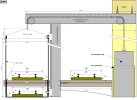

The levels are respectively at 0,9 - 1,3 - 1.7 m. height and each of them covers a 4m. long straight track connected to a 3.4 m. long curved track.

See picture.

The cogwheel track has to be as short as possible in order to keep enough track length available for recieving the cogwheel loc and 3 wagons with total length of about 1,5 m.

Can anybody help me with some knowledge about the design limits of cogwheel track?

I am not planning to use cogwheel track in the bends because that makes things even more complicated.

Question 1:

What is the max allowable traight slope? Is 45 degrees really possible when pushing max 3 wagons?

The overall horizontal length of the cogwheel section will mainly depend on the max allowable slope.

But it will also depend on the necessary length of the two end sections, where the track curves back to the horizontal plane.

Question 2:

What is the max vertical curvature at the start and the end of the straight cogwheel track section?

This meant I could not enjoy the looks of all that beautifull LGB stuff.

So i decided to build 3 exposition layers with about 7,5 m. long double track, mounted against the windows of my garden room.

The floor space along the walls of this room serve as my in house station.

While the centre of the room is in use as a music studio. So far this works fine.

Now I am planning to build a cogwheel track in front of the tracks to reach the 3 levels using a cogwheel locomotive.

The levels are respectively at 0,9 - 1,3 - 1.7 m. height and each of them covers a 4m. long straight track connected to a 3.4 m. long curved track.

See picture.

The cogwheel track has to be as short as possible in order to keep enough track length available for recieving the cogwheel loc and 3 wagons with total length of about 1,5 m.

Can anybody help me with some knowledge about the design limits of cogwheel track?

I am not planning to use cogwheel track in the bends because that makes things even more complicated.

Question 1:

What is the max allowable traight slope? Is 45 degrees really possible when pushing max 3 wagons?

The overall horizontal length of the cogwheel section will mainly depend on the max allowable slope.

But it will also depend on the necessary length of the two end sections, where the track curves back to the horizontal plane.

Question 2:

What is the max vertical curvature at the start and the end of the straight cogwheel track section?