At the beginnning of this year, I added some Binnie Hudson Tipper Wagons to my L&B themed railway. Tippers were used during it's construction and also in 1925 during the building of the Parracombe bypass. In both cases small industrial locos provided the power.

At the last Peterborough show, I saw and fell in love with this cute little LGB loco. I thought it would be suitable for the tippers and I've always wanted to own at least one LGB loco. It was secondhand but appeared not used, apart from various holes drilled in it. This included a huge chunk out the back, in what looks like a botched attempt to add battery operation from a trailing wagon.

Taking it to bits was relatively easy. All the space in the boiler was taken up by a large weight. There is a small PCB underneath at the back (along with a further small weight) which connects the track pickups to the motor via some suppression components.

Whilst the loco is small there are several places for the battery and electronics, underneath both at the front and back, in the boiler and in the coal bunker. It's main use is pulling and pushing 4-6 tippers up and down a separate section of track which lies within a loop at one end of my layout and automation is required so it can do this unattended.

I'm quiet hopeless on the building/mechanical side (for example, those tippers were a challenge!) so get my enjoyment from designing and building the electronics. The requirements were as follows:

Powered by an 18650 Lithium Battery

Integral charger powered from track

ESP8266 controlled

Reed switches for on and off to remove the need for an external on/off switch

Manual and Automatic operation

No visible electronics

A block diagram of the system:

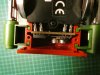

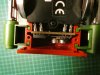

The existing PCB mounted underneath at the front is replaced with a PCB containing the bridge rectifier and the 5v switching regulator required to charge the battery.

The smokebox section of the boiler contains a 18650 lithium battery and a TP4056 based protection/charger. This provides all the discharge / charge protection required for a single Li-Ion battery and has the advantage of requiring a simple 5 volt supply for charging. From the nominal 3.8 volts from the battery, two voltages are required, 3.3 volts for the processor and RFID reader and 12 volts for the motor drive.

A Pololu 12 volt step up regulator, 3.3 volt step down regulator, H-bridge motor controller and the on/off circuitry fit on a small PCB at the cab end of the boiler. On either side of this PCB are mounted the on/off reed switches. A red LED in the cab illuminates when the loco is switched on. The Wemos D1 mini, ESP8266 processor board fits (just!) in the coal bunker.

An ID-12LA RFID reader is fitted underneath at the back of the loco. It is smaller, has a built in antenna and is much more sensitive than the ones I've previously used.

Location detection using RFID - G Scale Central

This allows the use of 20mm diameter tags on the track rather than credit card sized ones.

I've glued a magnet to the end of a pencil for switching on and off. It can also be switched off via the remote control, after a fixed period of inactivity or when the battery voltage drops to a certain level. The current drain from the battery is very low in the off state so the loco can be left for a long period without recharging.

All fit nicely together and nothing visible. It has worked fine since mid summer. In keeping with the L&B naming tradition (a 3 lettered river in Devon), it is called Sig. Picture taken before the driver was added.

Michael

At the last Peterborough show, I saw and fell in love with this cute little LGB loco. I thought it would be suitable for the tippers and I've always wanted to own at least one LGB loco. It was secondhand but appeared not used, apart from various holes drilled in it. This included a huge chunk out the back, in what looks like a botched attempt to add battery operation from a trailing wagon.

Taking it to bits was relatively easy. All the space in the boiler was taken up by a large weight. There is a small PCB underneath at the back (along with a further small weight) which connects the track pickups to the motor via some suppression components.

Whilst the loco is small there are several places for the battery and electronics, underneath both at the front and back, in the boiler and in the coal bunker. It's main use is pulling and pushing 4-6 tippers up and down a separate section of track which lies within a loop at one end of my layout and automation is required so it can do this unattended.

I'm quiet hopeless on the building/mechanical side (for example, those tippers were a challenge!) so get my enjoyment from designing and building the electronics. The requirements were as follows:

Powered by an 18650 Lithium Battery

Integral charger powered from track

ESP8266 controlled

Reed switches for on and off to remove the need for an external on/off switch

Manual and Automatic operation

No visible electronics

A block diagram of the system:

The existing PCB mounted underneath at the front is replaced with a PCB containing the bridge rectifier and the 5v switching regulator required to charge the battery.

The smokebox section of the boiler contains a 18650 lithium battery and a TP4056 based protection/charger. This provides all the discharge / charge protection required for a single Li-Ion battery and has the advantage of requiring a simple 5 volt supply for charging. From the nominal 3.8 volts from the battery, two voltages are required, 3.3 volts for the processor and RFID reader and 12 volts for the motor drive.

A Pololu 12 volt step up regulator, 3.3 volt step down regulator, H-bridge motor controller and the on/off circuitry fit on a small PCB at the cab end of the boiler. On either side of this PCB are mounted the on/off reed switches. A red LED in the cab illuminates when the loco is switched on. The Wemos D1 mini, ESP8266 processor board fits (just!) in the coal bunker.

An ID-12LA RFID reader is fitted underneath at the back of the loco. It is smaller, has a built in antenna and is much more sensitive than the ones I've previously used.

Location detection using RFID - G Scale Central

This allows the use of 20mm diameter tags on the track rather than credit card sized ones.

I've glued a magnet to the end of a pencil for switching on and off. It can also be switched off via the remote control, after a fixed period of inactivity or when the battery voltage drops to a certain level. The current drain from the battery is very low in the off state so the loco can be left for a long period without recharging.

All fit nicely together and nothing visible. It has worked fine since mid summer. In keeping with the L&B naming tradition (a 3 lettered river in Devon), it is called Sig. Picture taken before the driver was added.

Michael